We’ve all seen the Bali tattoo regret.

What most people don’t realise is timber floors can cop the same permanent mark – courtesy of rubber, pressure, and time.

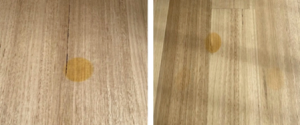

In flooring terms Tattooing relates to the appearance of permanent markings or imprints where a rubber article has made contact with the coated surface of a site or factory finished timber floor. The tattooing or staining of the floor is a penetration into the coating via solubility or diffusion of components of the rubber, resulting in a mark that cannot be removed from the surface. These marks often progress from a transparent yellow tone to a prominent solid black tone, relative to the type of rubber compound and the period of exposure. Closer inspection of the surface generally highlights that no damage to the coating is apparent with the ‘tattoo’ effect suspended in or under the coating.

We’ve all seen the Bali tattoo regret.

What most people don’t realise is timber floors can cop the same permanent mark – courtesy of rubber, pressure, and time.

In flooring terms Tattooing relates to the appearance of permanent markings or imprints where a rubber article has made contact with the coated surface of a site or factory finished timber floor. The tattooing or staining of the floor is a penetration into the coating via solubility or diffusion of components of the rubber, resulting in a mark that cannot be removed from the surface. These marks often progress from a transparent yellow tone to a prominent solid black tone, relative to the type of rubber compound and the period of exposure. Closer inspection of the surface generally highlights that no damage to the coating is apparent with the ‘tattoo’ effect suspended in or under the coating.

Whilst a relatively rare occurrence, the “Tattooing” effect is attributable to certain rubber compounds that may be used in the manufacture of items such as rubber furniture stoppers, rubber tyres, shoes or the rubber base material of mats etc which have maintained direct contact with the affected timber surface – usually in the company of a measure of weight related pressure or moisture saturation. The Tattoo or marking takes the shape of the portion of the object that is in direct contact with the floor and is most likely to occur when an object has remained in place for a significant period.

Examples:

Car Tyres

Instances of the tattooing effect have been observed where a soft compound car tyre has been in contact with a coated surface in areas such as a garage, car or tyre sales display, or where other forms of rubber tyre have been in contact with a floor.

Furniture Stoppers

Another common cause of tattooing is the rubber stoppers on tables and dressers, or other heavy furniture that is not moved regularly. Furniture moved regularly is less likely to facilitate this effect.

Rubber Undersided Mats

Other potential facilitators of tattooing are items that have an added rubber underside.

Rubber-based rugs and non-slip underlays have been responsible for instances of tattooing – suspected to be more prone when the item is wet while in contact with the floor surface.

Above: The rubber ‘anti-slip’ elements on the underside of the doggy bed have transferred onto the timber flooring surface.

Some rubber compounds are more susceptible

The tyres from this hoverboard, were observed to leave numerous marks or tattoo’s on this timber floor which were observed to appear in a shorter time likely due to the heating of the rubber tyres during use and facilitating a faster transfer from the rubber compound.

What rubber components are migrating and staining?

Non-marking rubber compounds can be formulated, such as those used in hospital beds and wheelchairs.

All rubber compounds contain 25 to 35% of free oil. There are two main types of oil. Aromatic (analogous to the effect of yellowing aromatic isocyanates) and Paraffinic. Car tyres and general black rubber products contain the migration staining Aromatic oils; non-staining rubbers (including some tyres) will contain the higher cost Paraffinic oils. Commodity products such as chair leg stoppers are formulated to a lower cost with the high levels of migratory staining Aromatic Oils.

Additionally, another key mobile ingredient are antiozonants and anti-oxidants. Most are free within the rubber matrix and can be powerful nitrogen containing amines, can be a major cause of contact staining or tattooing should they migrate onto and into a contacting surface.

There is an International test that considers Rubber impact on Staining of surfaces.

ASTM D925 – Standard Test Methods for Rubber Property—Staining of Surfaces (Contact, Migration, and Diffusion)

What we know and how to reduce the risk

It is known that the effect of tattooing is related to direct surface contact between a rubber item containing certain migratory staining chemicals (especially Aromatic oils and Amine antiozonants) and a coated timber surface where a reaction occurs over a period of time. Whilst it is difficult to identify all types of rubber that display a greater propensity to provide a tattooing affect, it is suspected that potential for staining may likely be increased in the presence of heat (such is in the case of tyres), strong solvents or moisture from items being wet washed whilst in place (such as rugs).

The type of coating can impact the susceptibility to tattooing / migration staining.

More prone are those type of coatings that are considered more breathable‘ or of a lower chemical resistance. However, all coatings can experience the effect but some can be much more resistant.

PLEASE NOTE THIS INFO SHEET IS EXCLUSIVE TO ATFA MEMBERS